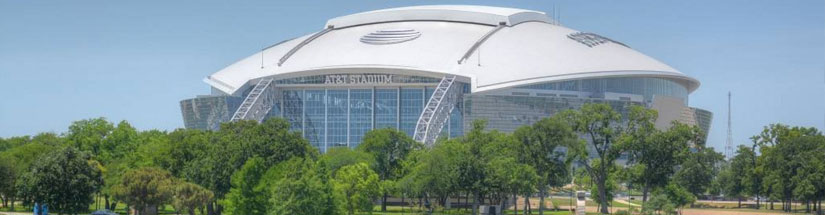

Precast operations are often highly optimized already, but the use of concrete maturity reveals enormous savings in both time and costs that impress even the most advanced precaster. For example, one producer felt that they had optimized their mix design for thousands of risers for the new Dallas Cowboys stadium. They were able to turn their casting beds over with a cycle of 18-24hrs, which is impressive on such a large scale. However, concrete maturity testing showed that they could lower their cement content significantly and still achieve the strengths required in the timeframe they needed. Making this small adjustment saved the producer “one rail car tanker-load of Portland cement in the first week of operation alone.” The Con-Cure system paid for itself in the first 7 days of operation at that particular plant in cement savings alone.