When concrete hardens (cures), it gives off heat proportional to its curing rate. The concrete maturity method is used to account for the combined effects of time and temperature on the strength development of concrete. By learning how much heat is released, an accurate estimate of the concrete strength can be determined. Generally, concrete in a structure cures at a MUCH faster rate than concrete in a test cylinder. This is due to the much larger mass of the structure, and better hydration which aids curing.

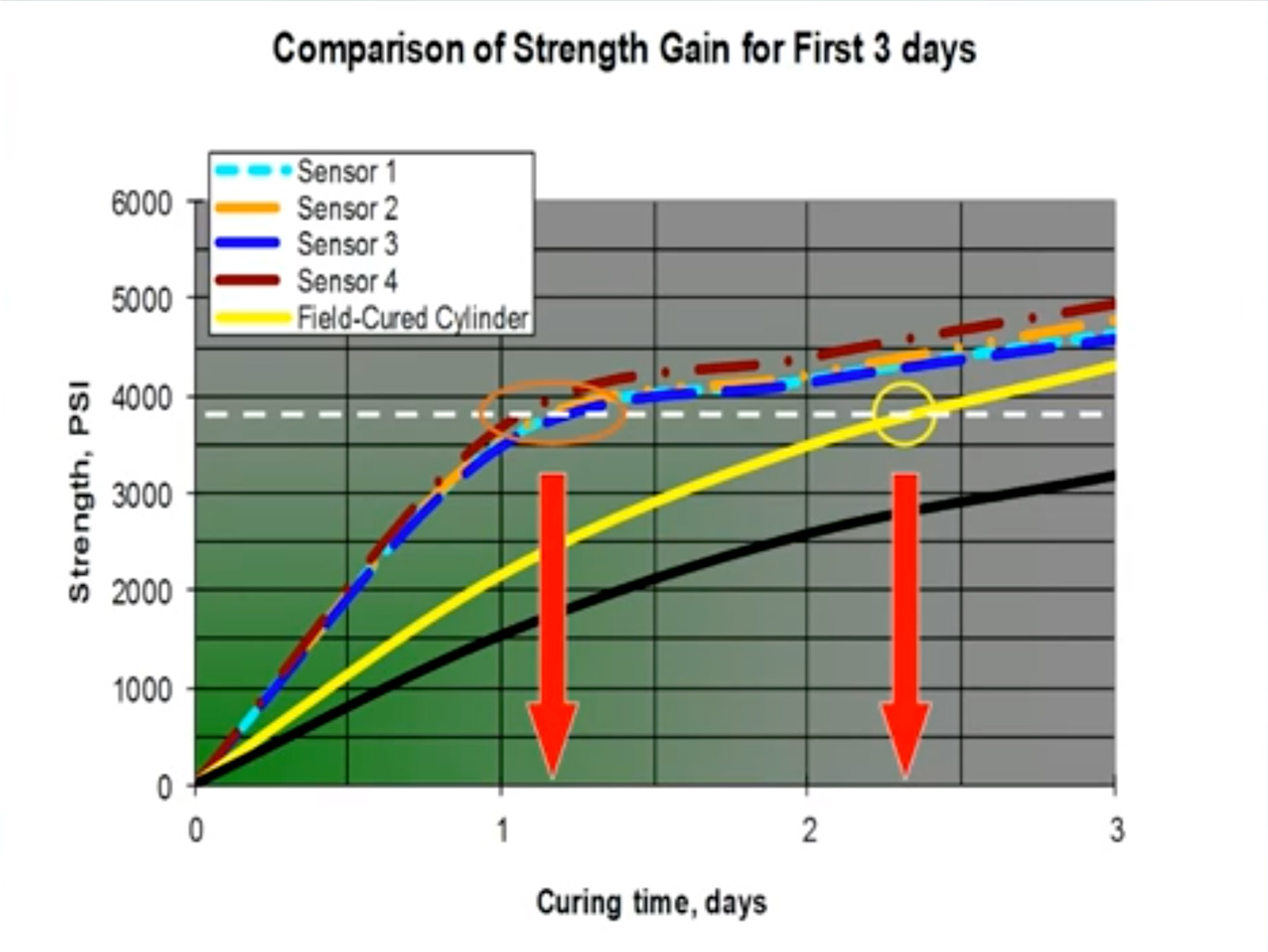

When determining the early-age strength of cast-in-place concrete, reliance on test cylinders can lead to problems. For example, if test cylinders are cured at a lower temperature than the structure, the cylinders would underestimate the strength of the slab, which means that critical construction operations are delayed unnecessarily. Or conversely, if the deck is cooler than the cylinders, the cylinders would overestimate the strength, a clear safety concern. Concrete maturity testing monitors the curing of the structure and compares it to the cylinder, to more accurately track strength gain in the structure, improving both safety and construction operations.

Concrete maturity testing has been a recognized ASTM Standard practice (C1074) for over 30 years. Click here to learn how Con-Cure NEX can help you on your next project.

How can Concrete Temperature Monitoring help improve concrete quality in non-ideal climates?

Experts agree that ideally concrete should cure for 7 days at temperatures between 65-85°F under 100% humidity. However, even the most conscientious builder knows this is simply not possible in most cases.

Because concrete maturity testing also tracks temperature history during the critical early-age curing process, it is often possible to take valuable steps to improve the cure before problems develop. For example, heat can be applied when it is shown that the concrete is getting too cold, thus ensuring completion of the hydration reaction needed for proper strength gain. Conversely, it has been proven that adding too much heat is detrimental to long-term durability and can lead to lower ultimate strengths, so taking steps to prevent overheating is also beneficial. Plus, if the contractor can avoid adding heat when it’s not necessary, the savings add up very quickly.

The Major Benefits of Concrete Maturity Monitoring

- Shorten construction cycles, because the in-situ (cast-in-place) concrete is typically far higher in strength than the test cylinders at the same age.

- Stress post tension and cycle formwork sooner – often much sooner.

- Reduce energy usage by terminating external heating operations as soon as the in-place concrete reaches required strength without having to wait for the cylinders to get there.

- Save money on concrete mixes by optimizing mix designs around in-place target strength times rather than on cylinder break times.